£7.75 delivery on orders excluding certain products & postcodes *

Sika BentoShield Max LM

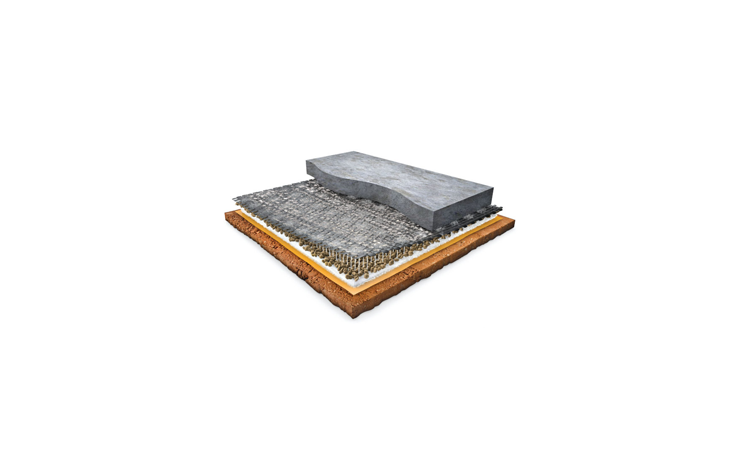

Sika® BentoShield® Max LM is a self healing waterproofing membrane that is resistant to contaminated soils, forming an automatic mechanical bond to freshly poured concrete. BBA Certificate 16/5342 for waterproofing structures.

Best Uses

Sika BentoShield Max LM is best used as a damp proofing, water proofing, tanking membrane for horizontal and vertical applications where buildings are expected to be subject to hydrostatic water pressure. It is also used on below ground reinforced concrete structures.

- Effective against diaphragm wall constructions.

- Direct application onto ground retaining concrete piling when placed within the piling - concrete interface

- Direct application within steel sheet piling – concrete interface

- Can be placed within the formwork.

- Below structural reinforced concrete slabs.

Approvals

- Conforms to the requirements of BS EN 1928 (24h/60 KPa) Water tightness to liquid water

- Declaration of performance CPR-0554-MAXLM-25-07

- CE Certificate No. 1301 – CPD - 0554

- EN 13491:2007 - Geosynthetic barriers “Characteristics required for use as a fluid barrier in the construction of tunnels and underground structures

- EN 13492:2004 - Geosynthetic barriers “Characteristics required for use in the construction of liquid waste disposal sites, transfer stations or secondary containment”

- EN 13493:2007 - Geosynthetic barriers “Characteristics required for use in the construction of solid waste storage and disposal sites”

- EN 13361:2004 - Geosynthetic barriers “Characteristics required for use as a fluid barrier in the construction of reservoirs and dams”

- EN 13362:2006 - Geosynthetic barriers “Characteristics required for use in the construction of Canals

- BBA Certificate 16/5342 for waterproofing structures

Application

The membrane is designed to work under confinement. When placing Sika® BentoShield® Max LM inside the formwork, the formwork must be removable & not the stay in-situ variety. Sika® BentoShield® Max LM products are not designed to be installed over ice or in standing water. Should the ground water contain strong acids, alkalies, or has a conductivity of 2,500 μmhos/cm or greater, water samples should be tested for compatibility. Rolls may compress slightly during storage. Membrane can be shaken once unrolled to return to their full length.

Sika® BentoShield® Max LM may be combined with other Sika products.

Approvals

- Conforms to the requirements of BS EN 1928 (24h/60 KPa) Water tightness to liquid water

- Declaration of performance CPR-0554-MAXLM-25-07

- CE Certificate No. 1301 – CPD - 0554

- EN 13491:2007 - Geosynthetic barriers “Characteristics required for use as a fluid barrier in the construction of tunnels and underground structures

- EN 13492:2004 - Geosynthetic barriers “Characteristics required for use in the construction of liquid waste disposal sites, transfer stations or secondary containment”

- EN 13493:2007 - Geosynthetic barriers “Characteristics required for use in the construction of solid waste storage and disposal sites”

- EN 13361:2004 - Geosynthetic barriers “Characteristics required for use as a fluid barrier in the construction of reservoirs and dams”

- EN 13362:2006 - Geosynthetic barriers “Characteristics required for use in the construction of Canals

- BBA Certificate 16/5342 for waterproofing structures

Technical Info

| Components: | Single Pack |

| Type: | Waterproofing tanking membrane |

| Finish: | n/a |

| Stock Colours: | Black woven / White non-woven geotextiles, yellow polyethylene laminate |

| Tintable: | No |

| VOC Content: | n/a |

| Volume Solids: | n/a |

| Suitable Substrates: | Freshly poured concrete |

| Application Method: | Brush, Roller, Airless Spray or Air-Atomised Spray |

| Mass per unit area: | > 5000 g/m2 |

| Resistance to Static Puncture: | > 1850N |

| Tensile Strength: | > 10 kN/m |

| Adhesion in Peel: | > 2,5 kN/m |

| Water Vapour Transimission: | < 1,0 x 10-11 m/sec |

| Water Tightness: | 70m |

| Effective Thickness: | Thickness: 6.5mm, PE Thickness: 0.3mm |

| Fully Cured: | days at 20°C |

| Shelf Life: | 2 years from date of production |

| Packaging: | Available in 1.1m x 5m rolls (5.5 sq.m) |