£7.75 delivery on orders excluding certain products & postcodes *

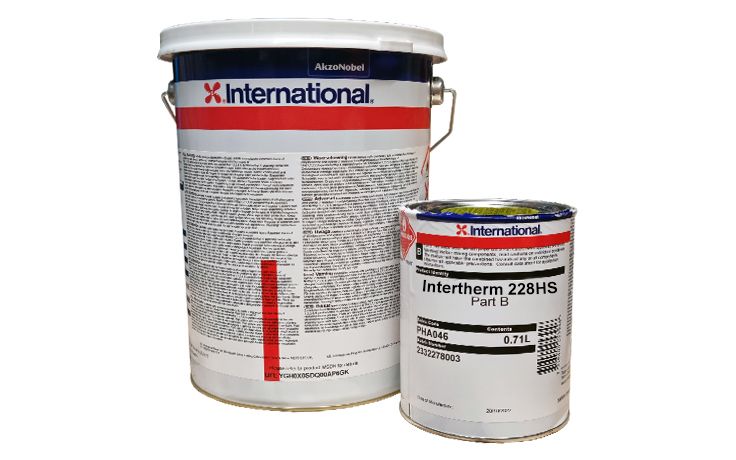

International Intertherm 228HS

International Intertherm 228HS is a highly cross-linked, two component, high build epoxy phenolic coating which combines properties of corrosion and chemical resistance when used in high temperature service.

Intertherm 228HS is a next generation epoxy phenolic coating based upon novolac resin technology.

Best Uses

Intertherm 228HS has been specifically designed to provide a corrosion resistant barrier when used to protect steelwork beneath thermal insulation in areas subjected to wet and dry cycling. Suitable for exposure in a wide range of highly corrosive environments, including insulated and uninsulated carbon and stainless steel for use on the exterior of pipework, process vessels etc., operating at temperatures up to 230°C (446°F).

Intertherm 228HS has excellent resistance to "thermal shock" experienced during rapid temperature cycling.

Application

All surfaces to be coated should be clean, dry and free from contamination. Prior to paint application all surfaces should be assessed and treated in accordance with ISO 8504:2000. Where necessary, remove weld spatter and where required smooth weld seams and sharp edges. Oil or grease should be removed in accordance with SSPC-SP1 solvent cleaning.

Abrasive Blast Cleaning

This product must only be applied to surfaces prepared by abrasive blast cleaning to Sa2½ (ISO 8501-1:2007) or SSPC-SP10. A sharp, angular surface profile of 50-75 microns (2-3 mils) is recommended. Intertherm 228HS must be applied before oxidation of the steel occurs. If oxidation does occur the entire oxidised area should be reblasted to the standard specified above. Surface defects revealed by the blast cleaning process should be ground, filled or treated in the appropriate manner.

Power Tool Cleaning (Small Areas Only)

Intertherm 228HS is suitable for application over power tool cleaned surfaces prepared to a minimum of SSPCSP11. Note, all scale must be removed and all areas which cannot be prepared adequately should be spot blasted to a minimum standard of Sa2 (ISO 8501-1:2007) or SSPC-SP6.

Stainless Steel

Ensure surface is clean, dry and free from metal corrosion products prior to coating. Light sweep with non-metallic and chloride free abrasive (e.g. aluminium oxide or garnet) to obtain anchor profile of approximately 50 microns (2 mils).

Material is supplied in two containers as a unit. Always mix a complete unit in the proportions supplied. Once the unit has been mixed it must be used within the

working pot life specified. Agitate Base (Part A) with a power agitator. Combine entire contents of Curing Agent (Part B) with Base (Part A) and mix thoroughly with power agitator.

| Components: | Two Pack |

| Type: | Epoxy Phenolic |

| Finish: | Eggshell (approx. 25%) |

| Stock Colours: | Grey and White |

| Tintable: | No |

| VOC Content: | 167 g/L |

| Volume Solids: | 70% |

| Suitable Substrates: | For steelwork |

| Application Method: | Airless Spray, Air spray, Brush, Roller |

| Theoretical Coverage: | 4.67 m2 per litre at 150 microns DFT and stated volume solids |

| Wet Film Thickness (WFT): | 143 - 214 microns |

| Dry Film Thickness (DFT): | 100 - 150 microns |

| Induction Time: | - |

| Pot Life: | 4 hours at 15°C |

| Touch Dry: | 7 hours at 15°C |

| Overcoatable: | Between 24 hours and 4 days at 15°C |

| Hard Dry: | 16 hours at 15°C |

| Cleaner / Thinner: | International GTA220 (or International GTA415) |

| Shelf Life: | 12 months at 25°C (77°F). Subject to re-inspection thereafter. Store in dry, shaded conditions away from sources of heat and ignition. |

| Packaging: | Available in 20 Litres |