Recently we had an enquiry regarding the consumption rate of various paint coatings. We discussed why the theoretical spreading rate and the practical usage rate were significantly different. In most cases, wastage is caused by some paint being left in the tin, paint left on the roller and in the tray, and over-spraying past the object you are painting. As a general rule, contractors allow for a 10-20% wastage for most coatings.

What Are Theoretical Coverage Rates?

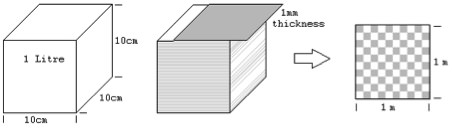

The theoretical coverage rates quoted on the manufacturer’s data sheets all conform to a pure mathematical formula. For example, one litre of paint applied over a perfectly smooth surface at a thickness of 1000 microns (1mm) will cover one square metre. Due to the clever metric system, we are able to describe one litre in volume as equal to a 10cm cube. Imagine one litre of solidified paint in the form of a 10cm cube, cut in to 100 x 1mm slices or tiles. If you were to arrange these tiles in a 10 x 10 arrangement, you will cover 1 square metre. This is the basis on which theoretical coverage rates are calculated.

In practice, applying paint such as the Rust-Oleum Fillcoat Fibres, consistently at exactly 1000 microns on a surface is unlikely, especially with a brush or roller. A coating which is 50 microns (1 20th of a millimetre) thicker than the theoretical rate represents a 5% increase in the product consumed.

Shop primers are a very thin anti corrosive coating designed to prevent corrosion whilst blast cleaned metal products are temporarily stored. A shop primer which is theoretically 15 microns in thickness, which is applied slightly thicker at 18 microns in practice, represents a 20% increase in consumption, very significant when the difference is only 3 microns (a 333rd of a millimetre).

Preparation

Before metal is painted, it must be blast cleaned to remove mill scale and rust just prior to painting. Blast cleaned metals are often given a surface profile of between 50-70 microns. That is the depth of the indentation caused by the impact of the particles on the surface of the metal object. So, to ensure the indentation on the surface is filled with paint and that you are then creating a layer of paint that covers over the highest point of metal, you will in practice be using a far greater amount than the theoretical rate as you are not applying the product onto a smooth surface.

Here we see a theoretical layer of primer on a perfectly smooth metal surface. At 18 microns DFT the theoretical coverage rate is calculated thus:

Volume solids x 10

DFT

The volume solids are a percentage of product suspended in its liquid state (this data is found on the manufacturer’s data sheet). As the wet film of the paint dries, the liquid (whether it be water or solvent) evaporates and leaves behind the Dry Film Thickness of paint. A paint with 28% solids and a DFT of 18 microns gives us a theoretical coverage rate of 15.55 m2 per litre.

Blast cleaned metal with a profile of 50 microns will look something like this:

The paint has filled in the 50 micron deep indentations and has been applied to ensure there is a thickness of 18microns over the highest point to ensure no bare metal is exposed which otherwise will allow corrosion.

A DFT may only take a reading through the coating to the red line, and may not allow for the additional product used. In this example, the average additional thickness of paint is 25 microns, underneath the 18 microns required.

In total, a DFT of 43 microns has actually been used in this theoretical diagram:-

The increase from 18 microns to 43 microns is a factor of 238%. This means the theoretical coverage rate is significantly reduced down from 15.55m2 per litre, to 6.53m2 per litre. The extra allowance or ‘wastage’ for the blast cleaned metal is near 58% when compared to the theoretical rate. The percentages are significant when we look at a shop primer, but less so for a thick waterproofing paint or a thick epoxy floor coating.

Here we see a Dry Film Thickness (DFT) Gauge used for determining the thickness of paint after the paint has been applied and allowed to dry. The gauge uses an electromagnetic field which induces a current or a high frequency signal. This can measure the paint thickness on either ferrous or non-ferrous metals.

Wet Film Thickness

During application, a Wet Film Thickness Gauge can be used moments after the paint is applied. Referring to the paints data sheet, you will see at what thickness the paint needs to applied in its liquid state (WFT) in order to achieve the specified dry film. This is the preferred method by the majority of contractors, as it allows the opportunity for correction and adjustments during application to ensure it is applied at the sufficient rate.

As you can see, this is a very simple but effective device when applying paint to a flat surface. The instructions on use can be seen in the photo.

The practical consumption rates of paints can be difficult to determine accurately due to the texture (and porosity) of the surface you are painting. In conclusion, always order more paint than is theoretically required. Theoretical consumption rates are used as a guide, but as you can see, there are many factors which affect the actual consumption rate. Once you have used up a tin or two, try to gauge if you feel you have sufficient paint to finish the project. We can often despatch additional paint within a day or two so that you can finish the job.

For more information or assistance, don’t forget to contact the Promain team to assist you in achieving a quality result.