Based in Burnaston just outside of Derby, this manufacturing plant has assembled production of their Avensis, Corolla and Auris Toyota models. Employing over 3000 staff, when it came time to renew the floor in one of the warehouse units used for storage of steel components, technical advice was required to get the best product for the job.

Understandably, the floor coating required in any manufacturing plant needs to be both hard-wearing but also with a long life. Originally laid was standard Protectakote. However, due to the frequent use of forklifts going in and out of the unit, the rubber from the coating ripped rubber off the fork lift tyres. An expensive problem to have!

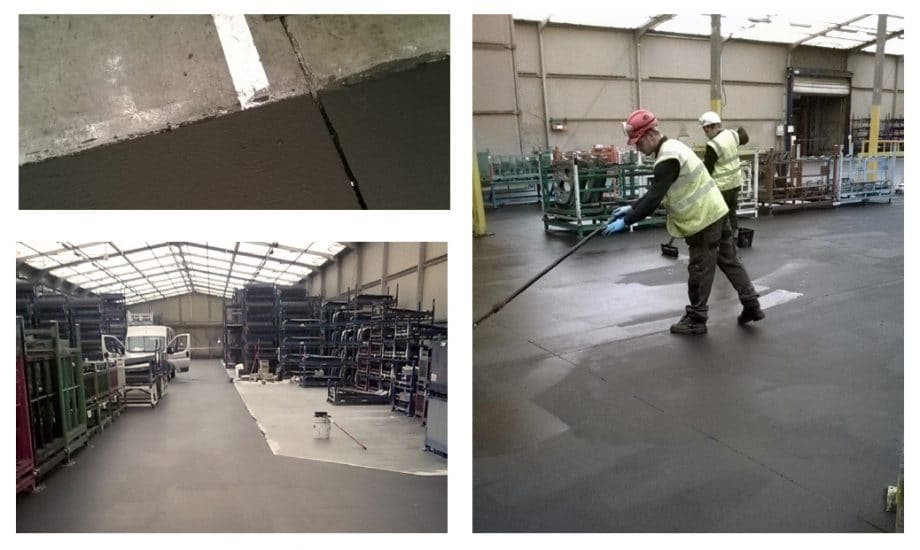

Able to withstand the intense use of multiple forklifts and storage of heavy steel components, it was suggested that Protectakote’s Safekote Anti Slip Floor Paint was used as it incorporates non slip particles within its polyurethane coating.

Introducing Protecta-Kote SafeKote

Protecta-Kote Safekote is a moisture-cure, aliphatic, polyurethane composition that provides ease of application with an extremely abrasion and weather resistant film. This product has an attractive, non slip, low gloss finish. It is easy to clean and maintain. Henceforth, it is ideal for warehouse floors. Safekote offers attractiveness and is available in standard marine colours. It will not fade or yellow from UV degradation. However, safety colours and other colours are available on request. Black was chosen for Toyota as the area being re-coated was being used to house steel components.

With 172x 4 litre tins used, covering over 16000 square foot, it was important that the product be easy to apply with fast drying capabilities. Safekote is ideal as it is suitable to be walked on or driven over after only 4 hours. Safekote also offers protection against diesel, petroleum and many other solvents and acids – perfect for a vehicle manufacturing plant!

With 172x 4 litre tins used, covering over 16000 square foot, it was important that the product be easy to apply with fast drying capabilities. Safekote is ideal as it is suitable to be walked on or driven over after only 4 hours. Safekote also offers protection against diesel, petroleum and many other solvents and acids – perfect for a vehicle manufacturing plant!

As of 2017 with the coating being down for 3 years now under the most severe of use, the Protectakote Safekote coating is still down and coping.

Contact Promain’s technical team today to see if this product can work for your job.