As we rapidly approach the external painting season and warmer drier weather, we would like to share our technical expertise in relation to painting external brick work. Below you will find all the factors that you should consider before you start any project.

Factors to consider

Moisture Content

Brickwork can often absorb water as a result of storage without protection and exposure to wet weather. Excessive moisture content will affect the adhesion of most type of paints. Moisture content can also lead to blistering and flaking as well as encouraging the growth of mould and algae. Additionally in combination with the alkalis and salts contained within brickwork, a high moisture content can lead to other problematic issue such as efflorescence, alkaline attack and staining which we will cover in more detail further in to the blog.

Until the moisture content of brickwork has substantially dried out there will be the potential for any coating to fail or be met with other issues. Even in warm and favourable conditions drying out can take a long time. A good rule of thumb is to allow 1 week of good drying conditions for each 5mm thickness of wet material, typically 4-6 weeks will be sufficient.

Best practice to determine moisture content of a substrate would be to use an electronic moisture meter. Moisture meters are easy and convenient to use. They enable a number of readings to be taken quickly across a substrate.

Generally for brickwork, a moisture content of anything below 18% will be OK to apply paint, however please do always consult the manufacturers technical datasheet as it will advise the optimum moisture content for application.

Efflorescence

Salt and minerals within the bricks leach out as moisture leaves the brickwork. This forms a crystalline deposit on the surface. It is whitish in appearance, and is sometimes referred to as “whiskers”.

Generally with water based paints which are typically vapour permeable efflorescence can pass through without any disruption although adhesion can be impaired. It is best practice not to apply any paint even if vapour permeable until the efflorescence has ceased and deposits have been treated and removed.

The best way to remedy efflorescence would be to firstly remove the deposit form the brickwork using a stiff broom. The next step would be to treat the brick work with Centrecoat R11 Salt Neutraliser. This is a very easy to use treatment. Simply dampen the surface that requires treatment with water. Spray or pour Salt Away onto the affected area ensuring complete coverage. Take care not to over-spray Centrecoat R11 onto surrounding areas particularly lawns, plant beds, metal surfaces. Leave Salt Away for 5-10 minutes depending on levels of efflorescence. Wash down area with clean fresh water. Repeat application may be necessary for badly affected areas to ensure all the salt and mineral have been removed. Allow the brickwork to then dry out before application of paint.

Alkalinity

Concrete blocks and mortar joints in brickwork contain either Portland cement or lime which is strongly alkaline, which can cause negative effects on paints. Alkalinity will diminish with ageing but this can take several years. This is generally a problem with newer brickwork. Solvent based paints are susceptible to being saponified (softened or liquefied) by alkalis present in the moisture contained within the brick. This can be overcome by using an alkali resistant primer such as Rustoleum Primer 44 HS Primer which is based on a chlorinated rubber. This primer could then be over coated with a breathable topcoat of Rustoleum Murfill Renovation Paint.

Water based paint system are not attacked in the same way but can be weakened or bleached by strong alkalis. The best practice would be to use an alkali resistant water based system. Mapei have a durable masonry paint system known as Silancolor which is alkali resistant. The Mapei paint system would consist of 1 coat of Silancolor Primer followed by 2 coat of Silancolor topcoat. This system could also be used on a lime render which are also highly alkali.

Porosity

Bricks vary considerably in porosity and absorption according to their manufacturing process, density and aggregate used. Even the densest type of bricks are generally porous enough to provide adhesion for paint coating. The more open and porous brick types would require you to thin the first application of primer or paint in accordance with manufactures instruction. Also if this brick type are located in an exposed environment a more protective system should be considered. A good paint system for brickwork in exposed areas would be to first prime with Rustoleum Mathys Pegafix with 2 coats of Murfill waterproofing coating. This system is approved by Trinity House for use on Lighthouses and is backed by a 10 year guarantee.

Staining

When bricks are produced they can contain iron oxide in the raw materials. When water-based paint are applied this can bleed through and can cause surface rust staining. If this does occur a stain blocking primer such as Zinsser Bullseye 1-2-3 Plus, as it contains stain blocking and rust prevention additives to prevent this.

Best Practice

Selecting a paint system

You will need to consider many factors when selecting a paint system for brickwork. Location is an important factor as a building that is located in an inner-city environment would be more susceptible to carbonisation and dirt pick caused by exhaust fumes and Co2, we class this environment as C3. This type of brickwork would require coating with a system such as Glixtone High Performance Masonry Paint AC1 which would protect against these types of atmospheric attack.

Brickwork in a coastal or locations that suffer from exposure are subject to harsh weather and salt spray. We class this type of environment as C5-M. A good paint system for coastal location or exposed area would be Rustoleum Murfill Waterproofing Coating, a highly weather resistant and waterproofing paint system.

Breathability should be a feature of any paint coating that you apply to external masonry and brickwork. Any coating you apply should be microporous allowing moisture in the brick to escape in the form of a water vapour. Applying a non-breathable paint could lead to moisture entrapment and problematic damp issues.

When selecting a paint system for brickwork, you should also consider an Elastomeric or a paint coating that can stretch. Applying a paint that is elastomeric allows the coating to stretch and contract with the natural movement of the building without cracking or splitting. As a crack or split in paintwork is not just unsightly but a weak point for the ingress of moisture.

Always consult the manufacturer’s technical data sheet before application of any paint system. If you are in any doubt, please do not hesitate to contact the Promain technical team for assistance.

Surface preparation

You will need to clean the brickwork with a stiff nylon brush to remove any loose material present on the surface. Remove and treat any efflorescence as per previous instruction.

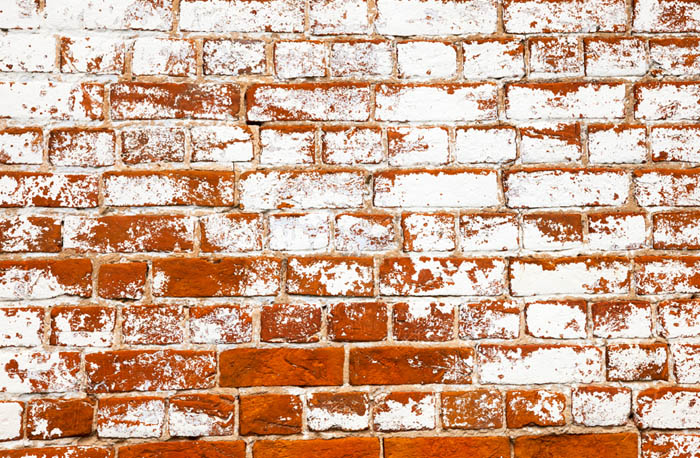

Older brickwork that is unpainted and heavily soiled may require a more intensive cleaning, such as jet washing. Once cleaning is complete, allow time for the brickwork to dry.

Previously painted brickwork will need to have any loose or flaking material removed and then also be cleaned and allowed to dry. It is also wise to check compatibility with the paint you intend to use. If in any doubt try a small test area or consult the Promain technical team for advice.

If any mould or algae is present on the surface this will require a fungicidal treatment, as this can cause a paint to lose adhesion. The best treatment for mould or algae would be Centrecoat GS36 fungicidal wash. To use dilute with clean water at a ratio of 20-1. Using a brush remove deposits from the surface, then using a backpack sprayer liberally apply to the brickwork and leave to work. Ensure the brickwork is completely dry before painting.

Stopping and filling

Any large voids, large holes in the brickwork will need to filled and repaired with a suitable masonry cement. You should repair small holes and minor surface defects with a masonry cement. These cements will need to fully cure and dry before applying any paint.

Systems for common brick types

External Painting: Fletton Bricks

This type of brick is very dense and has little porosity and is notoriously problematic to paint. These bricks were commonly used in the 1960’s & 70’s. The Zinsser Allcoat painting system (available in satin or gloss) will be compatible with this brick type, below I will describe the method of application.

Clean, prepare, and repair the brickwork as described earlier. You should then allow this to cure and dry before painting. The moisture content should not exceed 18% prior to painting.

Ensure air and surface temperature is between 10° – 32°C and relative humidity is less than 85%, with no rain forecast. Then using a brush or roller, prime all areas to be decorated with one full coat of Zinsser Bulls Eye 1-2-3 Primer Sealer. Allow a minimum drying time of 1 hour in optimum conditions (temperatures of 20°C).

After allowing the primer coat to cure. Apply 2 full coats of Zinnser Allcoat Exterior. Allowing a minimum drying time of 1 hour between coats in optimum conditions (temperatures of 20°C).

External Painting: Red Faced Bricks

This is a very common type of brick of average porosity which you can see commonly in use in construction across the UK. A good paint system for red faced bricks would be Rustoleum Murfill Renovation, see below method of application.

Before painting all repairs will need to be complete and the surface should be clean with preparation as described earlier. Before applying any paint, allow all repairs to fully cure. Allow the surface to dry.

Ensure air and surface temperature is above 5°C and relative humidity is less than 80%, with no rain forecast. Using a brush or roller apply a coat of Mathys Pegafix Impregnating Adhesion Primer, allow to cure for a minimum of 2-4 hours in favourable drying conditions (temperatures of 20°C). After allowing the primer coat to cure, using a brush or roller apply 2 coats of Rustoleum Murfill Renovation Paint. Allow a minimum of 24 hour between coats in optimum conditions (temperatures of 20°C).

External Painting: London Stocks

These types of brick are normally yellow in appearance and generally found in period properties built in the 1800’s. They are very porous and tend to be construct with lime based mortar joints, so specify alkali resistant systems for painting. A good coating for London stock bricks for this would be Mapei Silexcolor Mineral Silicate Paint as it is alkali resistant, see below the best method of application.

Before application ensure the air and surface temperature are above 8°C and no greater than 35°C with no rain forecast. Clean, prepare and repair any defects in the brickwork as previously detailed.

Ensure the brickwork is completely dry. Next use either a brush or roller to apply a coat of Silexcolor Primer. Allow this to cure for a minimum of 12 hours in favourable drying conditions (temperatures of 20°C).

After allowing the primer coat to cure, using a brush or roller apply 2 coats of Silexcolor Paint. Allow 24 hours of drying time between coats in favourable conditions (temperatures of 20°C).

If you are planning to paint brickwork and would like any technical assistance, please do not hesitate to contact our technical team on 0462 421 333 who will be happy to assist.