Let’s face it, unless you want to live in some dystopian Brutalist concrete jungle, concrete is pretty boring. It’s grey, it’s flat and it’s not very friendly.

However, concrete is an amazing building material. And even better than that, you can use it for floors, walls and even in the garden. It lasts almost forever, it’s cheap and it’s reliable. So maybe concrete isn’t that bad after all.

So, if you are are fed up with grey, grey, grey, read our article below to find out what concrete paint solutions Promain can provide you with.

The Concrete Answer

Yes, you definitely can paint your concrete surface. Painting concrete requires you to follow the proper preparation and application guidelines. Also, choosing the right kind of concrete paint or concrete stain would depend on the surface you’re working on. Our professional concrete paint guide will help you make the best painting decisions.

Why Concrete Is Tricky To Paint

Concrete is porous. Therefore, the first coat of paint will absorb into the substrate potentially giving a patchy finish. Many builders on concrete floors use a machine that creates a power floated floor. Due to the porosity of concrete, most paint systems require the first coat to be thinned down. This allows the paint to properly bind with the substrate.

What Is A Power Floated Floor?

A power floated floor is where a machine is used to close the surface of the concrete floor. By closing the surface, it then becomes non porous. The benefits of power floating a floor are because it will become much harder wearing and dust free. The result of this is the floor is much smoother and easier to clean. Many power floated floors are treated with products such as Sika Sikafloor Proseal W to seal the surface.

When Can I Paint Concrete?

New concrete is not recommend to be painted immediately. As a guide, concrete dries at a rate of 25mm of thickness per month. New concrete is often referred to as “green concrete”. It may be fine for you to walk on but not suitable for painting. Once the concrete has cured sufficiently, laitance would need to be removed before painting. Have a look at this article to find out more:

How To Remove Efflorescence and Laitance

If you need to paid your concrete floor before it is thoroughly dry, there are a number of

We do however have various products that are suitable for coating green concrete. If you want to seal new concrete have a look at Sika’s Sikafloor Proseal W. If you would like to paint your new concrete with a colour before it has properly cured, take a look at Remmers Epoxy Bs2000 and Remmers Epoxy BS 3000 SG. An alternative single pack product would be Bedec or Coo-Var Acrylic Floor Paint. These products are microporous allowing the concrete to dry.

If you are unsure about timescales or methodology, contact our technical team to discuss your individual project.

What Kind of Paint Can Be Used on Concrete?

It really depends on what the concrete item is. Below we have split up the concrete paint ranges into the most frequent uses:

Which Paints Should I Use For Concrete Walls?

As with all paints you get what you pay for. The better the quality of the paint the longer it will last. For a good internal or external wall paint we would suggest products such as the Mapei Silancolor range. If you concentrating on an external wall only, we would recommend one of our masonry paints.

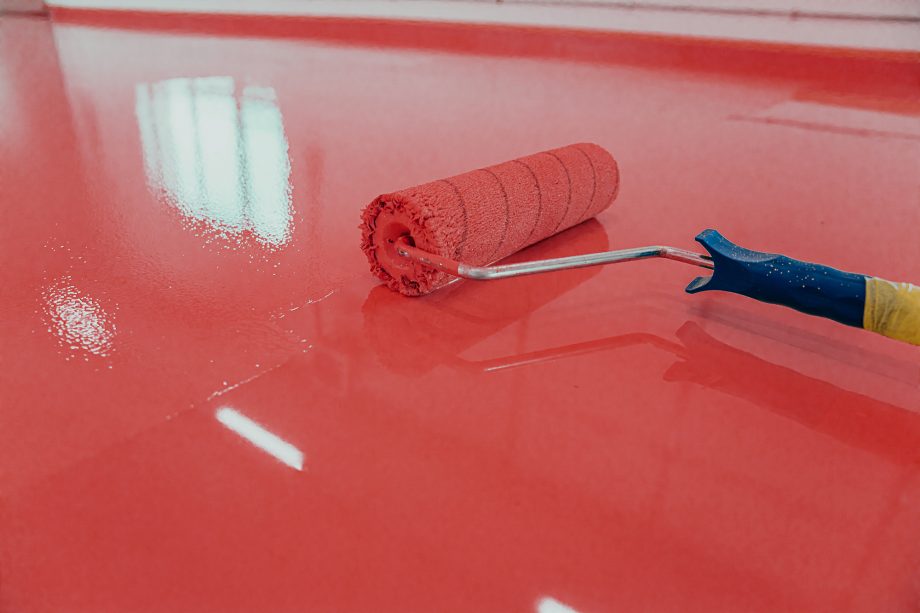

Which Paints Should I Use For Concrete Floors?

We would recommend one of our specialist garage floor paints for garages. For driveways, we would recommend a product from our driveway range. Ideal paints for patios are found in our patio paint category.

We do not recommend products for painting imprinted driveways as many have been sealed with polyurethane or silicon release agents in their manufacture.

For professional floors in galleries, hospitals, hotels, warehouses and other commercial environments, we would recommend a discussion with our technical team. We have a huge range of industrial floor paints that are suitable for various applications depending on the use of the area.

- Anti Slip Floor Paints

- Balcony Coatings

- Electro Conductive Floor Coatings

- Floor Primers

- Industrial Floor Paint

- Sika Floor Paint

- Workshop Floor Paint

- FeRFA Coatings

FeRFA is a flooring association that provide category identifiers for certain grades of floor coatings from 1 to 8.

BS 8204 Part 6 Synthetic Resin Flooring Type Categorisation

| FeRFA No | Type | Description | Duty | Typical Thickness |

| 1 | Floor Seal | Applied in 2 or more coats. Generally solvent or water borne | LD | > 150μm |

| 2 | Floor Coating | Applied in 2 or more coats. Generally solvent free | LD / MD | 150 – 300μm |

| 3 | High build floor coating | Applied in 2 or more coats. Generally solvent free | MD | 300 – 1000μm |

| 4 | Multi-layer flooring | Aggregate dressed systems based on multiple layers of floor coatings or flow-applied flooring, often described as sandwich systems | MD / HD | > 2mm |

| 5 | Flow-applied flooring | Often referred to as ‘self-smoothing’ or ‘self-levelling’ flooring and having a smooth surface | MD / HD | 2 – 3mm |

| 6 | Resin screed flooring | Trowel-finished, heavily filled systems, generally incorporating a surface seal coat to minimise porosity | MD / HD | > 4mm |

| 7 | Heavy duty flowable flooring | Having a smooth surface | HD / VHD | 4 – 6mm |

| 8 | Heavy duty resin flooring | Trowel-finished, aggregate filled systems effectively impervious throughout their thickness. | VHD | > 6mm |

LD – light foot traffic, occasional rubber tyre vehicles, MD – regular foot traffic, frequent fork lift truck traffic, occasional hard plastic-wheeled trolleys, HD – constant fork lift truck traffic, hard plastic wheeled trolleys, some impact, VHD – severe heavily loaded traffic and impact

How Do I Paint A Power Floated Floor?

The best method of preparing a power floated floor for painting is either diamond grinding or blast tracking. Have a look at our video to see how it’s done:

Alternatively, an adhesion primer such as Rust-Oleum 3333 can be applied directly to the power floated floor before a suitable topcoat. Suitable topcoats include Rust-Oleum Pegakote – a 2 pack water based epoxy.

Which Paints Should I Use For Industrial Concrete?

For multi storey car parks we recommend our range of anti carbonation paints. These have been formulated to stop the effects of exhaust fumes attacking the concrete and the reinforcing rebars.

For fire exits and stairwells, we recommend our range of high visibility products to ensure your staff and customers are safe when they need it.

For clear protection on concrete, we recommend products such as Keim Lotexan or Centrecoat All Surface Protector.

Do I Have To Paint Concrete? I Like It As It Is!

Not if you don’t want to. You should however think of using a concrete sealer. Using a sealer will stop dusting and make the concrete a lot easier to clean spills up from. The last thing you want is some oil or drink spill forever staining your concrete wall or floor.

For clear concrete protection, we recommend Keim Lotexan or Centrecoat All Surface Protector.

We distribute a wide range of concrete sealers; take a look at our category page for our full range:

https://www.promain.co.uk/car-park-repair-and-maintenance/concrete-sealers.html

Preparation: How Do You Paint Over Old Concrete?

First off, exactly how old is this concrete? Are you hoping a few layers of paint will hide a multitude of sins such as cracks, knicks and an uneven surface? Paint may be amazing stuff, but it is nothing without a suitable base to apply to. We recommend using a suitable concrete repair mortar to get your old concrete in a fit state before painting.

Concrete repair mortars come in a range of ratings from R1 – R4, with R4 being the highest rating. Professional users apply R4 mortars to reinforce industrial concrete. Unless you are looking to build an industrial train bridge over your property, R4 might be a bit overkill for most domestic users! For a domestic market, Rust-Oleum have a range of concrete repair mortars.

Our concrete repair mortars can be found here:

- Concrete Floor Repair

- Concrete Wall Repair

- R2 Class Approved Mortar

- Class R3 Approved Mortar

- Class R4 Approved Mortar

Conclusion

Always refer to your paints product data sheet prior to preparation adn application. These are available on the website under each product page.

Promain are passionate about paint. Our technical team are on hand for all your concrete paint advice within your individual circumstance. Contact our technical team today for the best paint advice and products on the market.