£9.95 delivery on orders excluding certain products & postcodes *

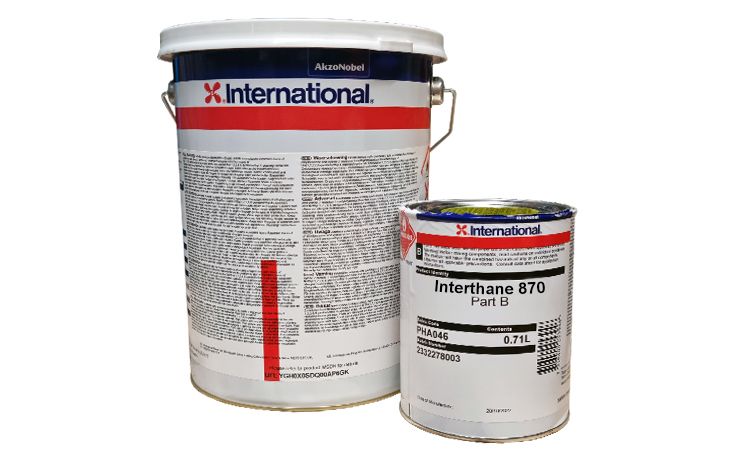

International Interthane 870

International Interthane 870 is a two part, high build, acrylic polyurethane finish, excellent durability, long term recoatability. Suitable for new construction and industrial maintenance. Semi Gloss finish. Network Rail - M24. N9. M34

Best Uses

International Interthane 870 is suitable for use in both new construction and as an industrial maintenance finish which can be used in a wide variety of environments including offshore structures, petrochemical facilities, bridges, pulp and paper mills, and in the power industry.

International Interthane 870 is particularly designed for use in areas where a high gloss is either not desired or where a semi-gloss is the preferred option. Provides a versatile option where overcoating of intermediates in one coat is not possible using conventional high gloss polyurethane finishes.

Application

All surfaces to be coated should be clean, dry and free from contamination. Prior to paint application all surfaces should be assessed and treated in accordance with ISO 8504:2000.

Primed Surfaces: Interthane 870 should always be applied over a recommended anti-corrosive coating scheme. The primer surface should be dry and free from all contamination and Interthane 870 must be applied within the overcoating intervals specified (consult the relevant product data sheet). Areas of breakdown, damage etc., should be prepared to the specified standard (e.g. Sa2½ (ISO 8501-1:2007) or SSPC-SP6, Abrasive Blasting, or SSPC-SP11, Power Tool Cleaning) and patch primed prior to the application of Interthane 870.

IMPORTANT NOTICE: From 24th August 2023, adequate training is required before industrial or professional use of this product. Training can be accessed at: https://www.safeusediisocyanates.eu

Approvals

- Network Rail New Works Systems Approved - N1 Protective Treatment. Certificate Ref N1/112

- Network Rail New Works Systems Approved - N2 Protective Treatment. Certificate Ref N2/039

- Network Rail New Works Systems Approved - N2 Protective Treatment. Certificate Ref XN90/N2-099

- Network Rail New Works Systems Approved - N4 Protective Treatment. Certificate Ref XN90/N4-080

- Network Rail New Works Systems Approved - N9 Protective Treatment. Certificate Ref XN90/N9-088

- Network Rail Maintenance Systems Approved - M20 Protective Treatment. Certificate Ref XM93/M20-071

- Network Rail Maintenance Systems Approved - M21 Protective Treatment. Certificate Ref M21-037

- Network Rail Maintenance Systems Approved - M21 Protective Treatment. Certificate Ref XN92/M21-188

- Network Rail Maintenance Systems Approved - M24 Protective Treatment. Certificate Ref XM92/M24-152

- Network Rail Maintenance Systems Approved - M24 Protective Treatment. Certificate Ref XM92/M24-151

- Network Rail Maintenance Systems Approved - M34 Protective Treatment. Certificate Ref M34-007

- Network Rail Maintenance Systems Approved - M34 Protective Treatment. Certificate Ref M34-003

- Network Rail Maintenance Systems Approved - M34 Protective Treatment. Certificate Ref M34-004

- Highways Agency Approved - Item No. 169

Compatibility

The following primers/intermediates are recommended for Interthane 870:

- Intercure 200

- Interplus 356

- Intercure 200HS

- Interseal 670HS

- Intercure 420

- Interzinc 52

- Intercure 420HS

- Interzinc 52HS

- Intergard 251

- Interzinc 315

- Intergard 475HS

- Interzone 505

- Interplus 256

- Interzone 954

Technical Info

| Components: | Two Part |

| Type: | Acrylic Polyurethane |

| Finish: | Semi Gloss |

| Stock Colours: | Only tints |

| Tintable: | Yes, to a wide range of colours via the Chromascan system. Please note, bespoke tints are non refundable / exchangeable |

| VOC Content: | 280.0g per Litre |

| Volume Solids: | 56% |

| Suitable Substrates: | For metal surfaces |

| Application Method: | Airless Spray, Air Spray, Brush, Roller |

| Theoretical Coverage: | 4.5 m2 per litre at 125 microns |

| Wet Film Thickness (WFT): | 134 - 223 microns |

| Dry Film Thickness (DFT): | 75 - 125 microns |

| Induction Time: | - |

| Pot Life: | 3.5 hours at 15°C |

| Touch Dry: | 75 minutes at 15°C |

| Overcoatable: | After 16 hours at 15°C |

| Hard Dry: | 16 hours at 15°C |

| Cleaner / Thinner: | Clean all equipment immediately after use with International GTA713 |

| Shelf Life: | 12 months minimum at 25°C (77°F). Subject to re-inspection thereafter. Store in dry, shaded conditions away from sources of heat and ignition. |

| Packaging: | Available in 5 and 20 Litres |