£7.75 delivery on orders excluding certain products & postcodes *

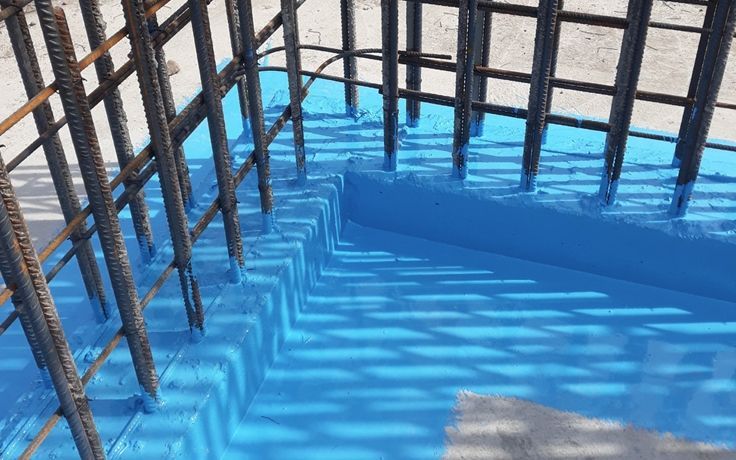

Fosroc Nitocote EP405

Fosroc Nitocote EP405 is a two pack gas resistant waterproof coating for waterproofing and protecting concrete structures. Also suitable for application to steel.

Best Uses

As a gas resistant waterproof coating, Nitocote EP405 is suitable for application to below ground retaining wall and foundation structures including construction joints to maintain waterproofing and ground gas protection continuity as part of a waterproofing and ground gas protection solution conforming to BS8102:2009 and BS8485:2015.

Fosroc Nitocote EP405 enables continuity of waterproofing and ground gas protection to be achieved in locations where the use of sheet membrane products is not

feasible. It is compatible for use with the Proofex range of sheet membranes.

Fosroc Nitocote EP405 is also ideal as a protective coating suitable for lining and waterproofing potable water retaining structures and surfaces subject to contact with foodstuffs. The cured film is corrosion, chemical and abrasion resistant and is suitable for application to basements, tunnels, tanks, silos, reservoirs, water treatment works, breweries, dairies and meat and food processing plants. The cured film is non toxic and meets the requirements of BS 6920.

- High build application

- Can be applied directly to mild steel and concrete

- Smooth, glossy, easy to clean surface

- Corrosion, chemical and abrasion resistant

- Can be applied to damp surfaces

- Waterproof

- Ground gas and water vapour barrier

- WRAS approved

Available in blue and white.

Specification Clauses

Ground Gas Resistant Waterproof Coating

The prepared designated concrete surfaces shall be coated with Nitocote EP405, a two pack epoxy coating applied in one or two coats to achieve a total coating thickness of 400 microns (0.4mm) in accordance with the manufacturer’s published instructions to achieve a sealed surface. Where required, the coating shall be broadcast with aggregate during the application process.

Protective Coating

The prepared designated concrete and / or steel surfaces shall be coated with Nitocote EP405, a two pack epoxy coating applied in two coats (blue + white) at a rate of 0.2 litres per square metre per coat in accordance with the manufacturer’s published instructions to achieve a sealed surface.

Approvals

- WRAS Approval Number: 1901528 - In accordance with WRAS listing, when Nitocote EP405 is used in contact with potable water, curing conditions are 21

days at 7°C - Type A waterproofing barrier as defined in BS8102:2009

- Ground gas-resistant liquid applied membrane compliant with BS8485:2015+A1:2019 Table 7

Technical Info

| Components: | Two Pack |

| Type: | Solvent Free Epoxy |

| Finish: | Smooth Gloss |

| Stock Colours: | Blue and White |

| Tintable: | No |

| VOC Content: | |

| Volume Solids: | 100% |

| Suitable Substrates: | Mild steel and concrete. |

| Application Method: | Stiff Brush |

| Theoretical Coverage: |

0.2 litres per m2 (2 coat application) 0.4 litres per m2 (1 coat application) |

| Wet Film Thickness (WFT): | |

| Dry Film Thickness (DFT): | 400 microns |

| Induction Time: | - |

| Pot Life: | 30 - 40 minutes at 20°C |

| Surface Dry: | |

| Overcoatable: | 6 - 18 hours at 20°C |

| Fully Cured: | 7 days at 20°C |

| Cleaner / Thinner: | Nitocote EP405 should be removed from tools and equipment with Fosroc Solvent 102 immediately after use. Cured material can only be removed mechanically. |

| Shelf Life: | 18 months if kept in a dry store between 5°C and 30°C in the original, unopened containers. Material from different batches shall be stored separately. |

| Packaging: | Available in 2.5 Kg |