£9.95 delivery on orders excluding certain products & postcodes *

Rustoleum Noxyde Pegarust

SKU

ID22513

UN1263 (Class: 3, Pk Grp III)

Solvent based primer and topcoat for ultimate corrosion protection in low temperatures.

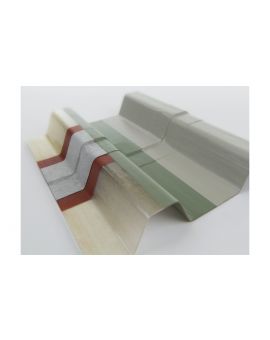

Available in 5kg and 20kg in 11 standard colours

From

£165.24

£137.70

In stock

Only %1 left

Product Description

Rustoleum Noxyde Pegarust is a single pack solvent-based elastic coating, which provides ultimate corrosion protection. It is a primer and topcoat in one and is suitable for use at low temperatures.

Please note, this product has a 3-4 week lead time.

Best Uses

Rustoleum Noxyde Pegarust is suitable for use on galvanised steel, bare or blasted metal, iron, zinc and aluminium. Both UV and impact resistant, it also protects against cracking and peeling and has an excellent resistance to chemical agents in the atmosphere.

Application

Pegarust can be applied by Brush, Roller, or Airless Spray.

Prepare the surface to be painted by degreasing and removing any rust according to the conventional de-rusting techniques (sandblasting Sa2 and mechanical sanding St3).

When using on new galvanised surfaces and new zinc, you will need to apply a coat of Metal Cladding Primer or PVDF Primer, prior to application of Pegarust.

Technical Details

Features & Benefits

- Ultimate corrosion protection, even in low temperatures or damp surfaces

- Protects against cracking and peeling

- UV and impact resistant

- Primer and topcoat in one

- Excellent resistance against chemical agents in the atmosphere

Technical Info

| Components: | Single Pack |

| Type: | Solvent Based |

| Finish: | Satin |

| Stock Colours: | Available in a range of 11 standard colours |

| Tintable: | No |

| VOC Content: | 500 g/l |

| Volume Solids: | 46% |

| Suitable Substrates: | Metal |

| Application Method: | Brush, Roller, Airless Spray |

| Theoretical Coverage: | ± 2.9 m²/l per coat (it is recommended to apply 2 coats) |

| Wet Film Thickness (WFT): | 345 µm |

| Dry Film Thickness (DFT): | 160 µm |

| Touch Dry: | 24-48 hours at 20°C |

| Overcoatable: | 24-48 hours at 20°C |

| Fully Cured: | 1 week at 20°C |

| Cleaner / Thinner: | Thinner 22 |

| Shelf Life: | Minimum of 2 years from date of production unopened |

| Packaging: | Available in 5 kg and 20 kg |