£9.95 delivery on orders excluding certain products & postcodes *

*Sika Sikafloor 310 PurCem

Please note, this product is now unavailable. Contact our Technical Team for alternative products.

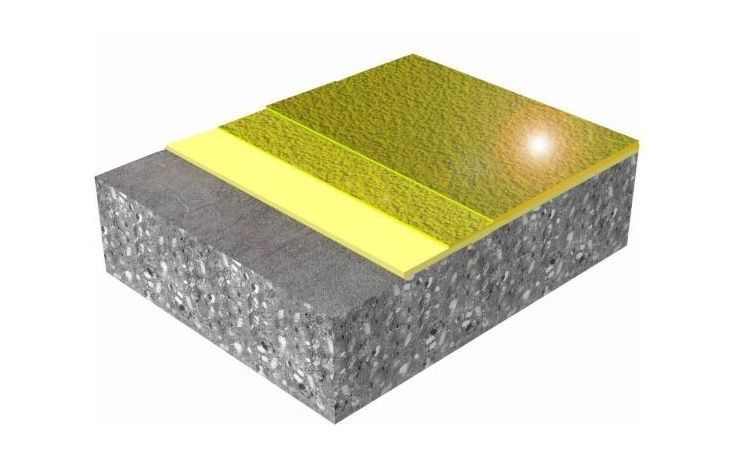

Sika Sikafloor 310 PurCem is a 3 component, water-based, coloured polyurethane hybrid topcoat with glossy finish suitable for hygienic and food production applications.

Best Uses

Sikafloor®-310 PurCem® may only be used by experienced professionals. Sikafloor®-310 PurCem® is used as a top and wear coat layer in Sikafloor® PurCem® Gloss system build ups and coating on horizontal surfaces (coving). Suitable as a hygienic coating for food production areas.

- Good chemical resistance

- Gloss and scratch resistance surface

- High mechanical resistance

- High glass transition point

- Non tainting / odourless

- VOC free and environmental friendly

- Moisture tolerant

Part of the following systems:

- Sikafloor® PurCem® HB-21 Gloss - Heavy to medium duty, broadcasted, glossy, light anti-slip PUCEM hybrid screed

- Sikafloor® PurCem® HB-22 Gloss - Heavy to medium duty, broadcasted, glossy, medium anti-slip PUCEM hybrid screed

- Sikafloor® PurCem® HB-23 Gloss - Heavy to medium duty, broadcasted, glossy, high anti-slip PUCEM hybrid screed

- Sikafloor®-29 PurCem® As a topcoat on Sikafloor®-29 Pur-Cem®

Application

Mix full part units only. The surface must be clean, dry and free of all contaminants such as dirt, oil, grease, coatings and surface treatments, etc. All dust, loose and friable material must be completely removed from all surfaces before application of the product, preferably by vacuum. Pull of strength shall not be less than 1.5 N/mm2. If in doubt apply a test area first.

Mix first the component A (pigmented liquid) thoroughly in the pail 10 – 15 sec. Then add component B (brown liquid) into A and mix together for 15 - 30 sec. using a stirrer in a low speed electric drill until homogeneous mixture. Then add component C to A+B mixing simultaneously with larger mixer. When the bag of component C is empty, continue mixing further 3 min depending on the temperature and the mixer efficiency.

Prior to application, confirm substrate moisture content, relative humidity and dew point. As a top coat Sikafloor®-310 PurCem® can be applied using a soft foam rubber squeegee and back roll with a medium pile roller. For further details please refer to the related system data sheet.

IMPORTANT NOTICE: From 24th August 2023, adequate training is required before industrial or professional use of this product. Training can be accessed at: https://www.safeusediisocyanates.eu

Approvals

- Complies with requirements of DIBt (2010) and AgBB for use in in indoor environment. Test report No. 392-2014-0018201A. Eurofin Product Testing

- Synthetic resin screed material according to EN 13813:2002, Declaration of Performance 60258591, and provided with the CE marking Taint potential. Repot No. S/REP/134217/3 Campden BRI (Chipping Campden (Ltd)

- Food Industry Approval. Certificate of Compliance to be used safely as a floor coating in food sector. Short term contact of the coating with the foodstuffs is safe as long as any hygienic regulations are not violated. Report No. 38653U14. ISEGA Forschungsund Untersuchungs-Gesellschaft mbH

- Cleanibility. Clean Room Suitable Material (Riboflavin test) test report SI 1501-752, Sikafloor®-310 Pur-Cem®. Fraunhofer Institute for Manufacturing and Engineering and Automation IPA

Systems

Sika Sikafloor 310 PurCem is used within the following systems:

- Sikafloor PurCem HB-21 Gloss

- Sikafloor PurCem HB-22 Gloss

- Sikafloor PurCem HB-23 Gloss

- Sikafloor PurCem HB-26 Gloss

See Data Sheets tab for System sheet downloadable PDF.

Technical Info

| Components: | 3 Part |

| Type: | Water based coloured polyurethane hybrid topcoat |

| Finish: | Gloss |

| Stock Colours: |

Beige, Dusty Grey, Yellow Green, Carmine Red, Agate Grey, Ultra Marine Blue, Golden Yellow Please note the stock colours do not have applicable RAL equivalents. |

| Tintable: | No |

| VOC Content: | 0.0g per Litre |

| Volume Solids: | |

| Suitable Substrates: | A top and wear coat layer in Sikafloor® PurCem® Gloss system build ups and coating on horizontal surfaces (covings) |

| Application Method: | Soft foam rubber squeegee and back roll with a medium pile roller |

| Theoretical Coverage: | Approx 0.3 - 0.9 Kg per m2 per mm |

| Wet Film Thickness (WFT): | |

| Dry Film Thickness (DFT): | |

| Induction Time: | - |

| Pot Life: | 22 - 25 minutes at 20°C |

| Touch Dry: | |

| Overcoatable: | Between 24 - 48 hours at 20°C |

| Fully Cured: | |

| Cleaner / Thinner: | Sika Thinner C |

| Shelf Life: | Part A: 9 months, Part B: 12 months, Part C: 6 months. Protect all from freezing. Protect Part C from humidity |

| Packaging: | Available in 5.80 Kg in total |