£7.75 delivery on orders excluding certain products & postcodes *

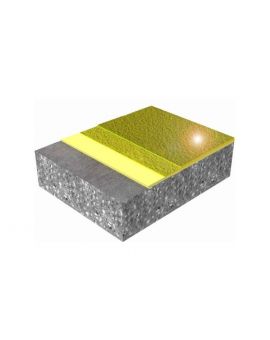

Sika Sikafloor 21 PurCem

Sika Sikafloor 21 PurCem is a multi-component, water based coloured polyurethane hybrid screed with self smoothing properties. It has a smooth, matt, impervious, hard wearing surface and is typically installed at 3 - 6 mm thickness.

Best Uses

Sika Sikafloor 21 PurCem is used as a scratch coat primer, base coat and wear coat layer in Sikafloor®Pur-Cem® system build ups, in areas of medium to heavy loading, high chemical exposure and abrasion.

- Good chemical resistance

- High mechanical resistance

- High glass transition point

- Non tainting /odourless

- VOC free and environmental friendly

- Can be applied to substrates with high moisture content (7 days old or mature damp concrete)

Sika Sikafloor®-21 PurCem® may only be used by experienced professionals.

Application

The surface must be clean, dry and free of all contaminants such as dirt, oil, grease, coatings and surface treatments, etc. All dust, loose and friable material must be completely removed from all surfaces before application of the product, preferably by vacuum. Pull of strength shall not be less than 1.5 N/mm2. If in doubt apply a test area first.

MIXING

Premix part A with a low speed electric stirrer and then add part B and mix for 30 seconds. For the colour pack version, premix part A neutral with a low speed electric stirrer and add part D to it. Mix until a uniform colour is achieved. Add part B and mix for 30 seconds. Use a double paddle (axis) mixer and gradually add part C (aggregate) to the mixed resin. Allow part C to blend for a further 2 minutes minimum, to ensure complete mixing and a uniform moist mix is obtained. During the operations, scrape down the sides and bottom of the container with a flat or straight edge trowel at least once (parts A+B+C) to ensure complete mixing.

Mixing Tools

Use a low speed electric stirrer (300 - 400 rpm) for mixing parts A and B. For preparation of the mortar mix use a double paddle mixer. Prior to application, confirm substrate moisture content, relative humidity and dew point. As a scratch coat Sikafloor®-21 PurCem® can be applied using a steel trowel. As a body coat Sikafloor®-21 PurCem® can be applied using a toothed trowel or pin screed, to the desired thickness, or a steel trowel. Remove air with a spike roller. For further details please refer to the related system data sheet.

IMPORTANT NOTICE: From 24th August 2023, adequate training is required before industrial or professional use of this product. Training can be accessed at: https://www.safeusediisocyanates.eu

Approvals

- Polyurethane screed for concrete protection according to the requirements of EN 1504-2:2004 and conforms to the requirements of EN 13813: 2002, DoP

02 08 02 02 001 0 000002 1088, certified by Factory Production Control Body, 0086, certificate 541325, and provided with the CE-mark - EN1186, EN 13130, and prCEN/TS 14234 standards, and the Decree on Consumer Goods, representing the conversion of directives 89/109/EEC, 90/128/EEC and 2002/72/EC for contact with food stuffs, according to test report by ISEGA, 32758 U11 and 32759 U11, both dated December 6th, 2011. (Tests performed on Sikafloor® -20/21/22/29 and 31 PurCem® in standard and LP versions).

- British Standards Specifications (BSS) acceptance for use in the UK

- Campden and Chorleywood Food Research Association, Ref. S/REP/125424/1a and 2a, dated 8th February, 2012

- Fire classification report according to EN 13501-1 from Exova Warrington Fire for Sikafloor®-21 Pur-Cem® No.317047, dated 24th of March, 2012

- Liquid water transmission rate test report from the Technology Centre, Ref. 15456 dated January 25th, 2012

- Abrasion resistance tests performed by Face Consultants Ltd., according to BS 8204-2:2003, report ref. FC/12/3850, dated January 17th, 2012. (Tests performed on Sikafloor® -20/21 PurCem®)

- Impact resistance values tested at PRA, Ref. nº 75221-151, dated January 11th, 2012

- Slip resistance properties according to DIN 51130 tested at MPI (Materialprüfung und Entwicklung), test reports refs. Nº 12-6639-S/12 and 12-6641-S/12,

dated August 7th, 2012. - Thermal expansion coefficient and freeze-thaw cycle resistance performed at RWTH / IBAC, report nº M-1614 dated May 29th, 2012.

Systems

Sika Sikafloor 21 PurCem is used within the following systems:

- Sikafloor PurCem HB-21 Gloss

- Sikafloor PurCem HB-22

- Sikafloor PurCem HB-22 Gloss

- Sikafloor PurCem HB-23

- Sikafloor PurCem HB-23 Gloss

- Sikafloor PurCem HS-21

- Sikafloor PurCem HS-26 Gloss

Technical Info

| Components: | Four Pack |

| Type: | Water Based Screed |

| Finish: | |

| Stock Colours: | See colour card |

| Tintable: | No |

| VOC Content: | 140 g/L |

| Volume Solids: | |

| Suitable Substrates: | For flooring |

| Application Method: | Steel Trowel, Toothed Trowel, Pin Screed, Spike Roller |

| Theoretical Coverage: | 1.93 Kg per m2 per mm |

| Wet Film Thickness (WFT): | |

| Dry Film Thickness (DFT): | |

| Induction Time: | - |

| Pot Life: | 22 - 25 minutes at 20°C |

| Surface Dry: | See datasheet |

| Overcoatable: | Between 24 hours and 48 hours at 20°C |

| Fully Cured: | See datasheet |

| Cleaner / Thinner: | Clean all tools and application equipment with Sika Thinner C immediately after use. Hardened / cured material can only be mechanically removed. |

| Shelf Life: | Part A: 12 months, Part B: 12 months, Part C: 6 months, Part D: 24 months. Protect all from freezing. |

| Packaging: | Available in 21 Kg |