£7.75 delivery on orders excluding certain products & postcodes *

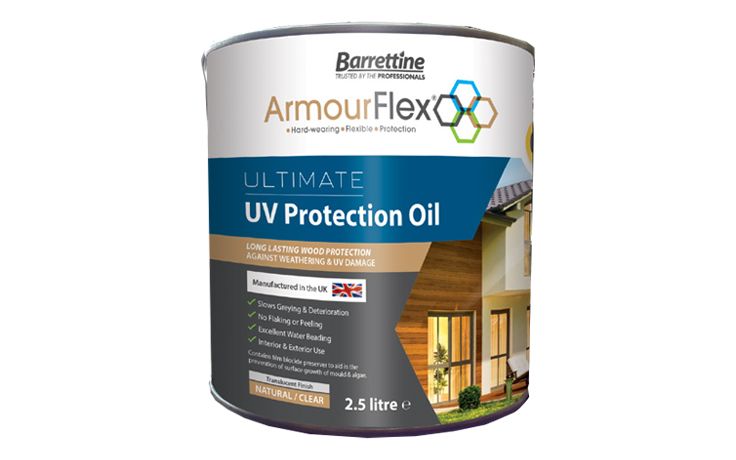

Barrettine ArmourFlex Ultimate UV Protection Oil

Barrettine ArmourFlex Ultimate UV Protection Oil is a technically crafted blend of natural oil and resins for wood, with a specialised UV absorber to shield against sun, rain and everything in between. For exterior wood and joinery.

ArmourFlex UV Protection Oil contains a careful balance of UV absorbers and antioxidants, designed to capture the damaging UV rays from the sun and dissipate them safely as heat. In this way, the ArmourFlex UV Protection Oil is able to defend the wood against greying and impart a subtle, enhanced warmth to its appearance. As a sacrificial product, the coating will become less effective over time (approx. 2 years depending on elevation and weather conditions), but a fresh maintenance coat can be easily reapplied.

Water-repellent oil and resins help to protect against warping and twisting (depending on wood type & quality of the wood. Oak as an example can naturally be inclined to twist and split). The surface biocide in the UV Oil helps prevent mould, fungi, and algae growth. Together, these form a microporous shield suitable for all exterior wood, especially external joinery, luxury cabins and wooden cladding. Armourflex UV Protection Oil can also be applied to internal wooden surfaces that are at risk of UV fading such as internal window sills.

Best Uses

Suitable for exterior use on all types of natural wood, including softwoods and hardwoods. Also suitable for modified/acetylated wood. UV protection oil can also be applied to internal wooden surfaces that are at risk of UV fading such as internal window sills. Can be used on engineered wood products such as plywood and OSB, providing they are modern. Older engineered wood, e.g., antique veneers, may contain glue which is susceptible to the solvents present. If you intend to apply Armourflex UV Protection Oil on to Fire protected cladding, consult with the cladding manufacturer first.

Compatible with the following Barrettine products, once dry:

- Barrettine Universal Preserver

- Barrettine Cladding Preserver

- Barrettine Cut End Preserver

- Barrettine Wood Preserver

- Barrettine Wood Reviver

- Barrettine Wood Protective Treatment

- Barrettine Decking Oil

- Barrettine Log Cabin Treatment

- Barrettine Mould and Mildew Cleaner

- Barrettine Super Concentrated Decking Cleaner

- Barrettine Danish Oil

- Barrettine White Knotting Solution

Can be used on structures where Barrettine Creosolve has been used previously and weathered for at least 3 months. Not compatible with Barrettine Shed & Fence Treatment, this must be removed first.

Application

Before use, test a small inconspicuous area with all products to be used, to ensure a satisfactory final finish and compatibility.

Reverse wood silvering using Barrettine Wood Reviver

Weathered timber can be treated with Barrettine Wood Reviver, which will restore greyed/silvered wood to its natural colour and remove some visible surface mould.

Test compatibility with or remove previous coatings

ArmourFlex UV Protection Oil is suitable for use over Barrettine Universal Preserver, Barrettine Cladding Preserver and Barrettine Timber/Cladding Cut End Preserver. It may be suitable for application over other minimal build wood stains or wood preservers, but this cannot be guaranteed and should be confirmed with a test patch. It is not suitable for use over opaque paints or varnishes. These must be removed either by sanding, heat gun or paint stripping. If choosing to use paint stripper, either Barrettine Paint Panther or Peelaway may be suitable.

Remove decayed wood

Any decayed wood and the surrounding area should be cut out and replaced, then the entire structure treated with Barrettine Universal Wood Preserver before application of this product.

Allow wood to acclimatise in situ

Fresh wood should be acclimatised in situ before coating, up to 6 weeks externally. It is important that wood can settle to its environment, to avoid future warping or cracking. This is especially important outdoors, in particular for hardwoods such as teak, oak and iroko, due to their high tannin and resin contents. The weathering off period will open the grain and rinse away surface tannins, preventing them from interfering with the coating and reducing future tannin runs. Failure to allow weathering off can lead to discolouration or patchiness, as surface tannins can leach unevenly when humidity is high. The higher the resin/tannin content, the longer the weathering off period required. Ask the wood provider for further advice.

Remove any resinous deposits

Remove resinous deposits with a scraper. Highly resinous woods such as cedar and hardwoods will be expected to have reduced absorption, so wipe with white spirit/methylated spirits to remove surface resins/oils. Knots will have a higher resin content so pay particular attention to these, to avoid an uneven appearance. Fill any cracks or gaps as necessary, using a suitable wood filler.

Test compatibility with ArmourFlex UV Protection Oil on a scrap of wood before use. Fillers which use sanding dust from the wood itself will achieve the closest colour match. Wax fillers are not compatible as they will not allow the product to absorb.

Sand wood to a smooth finish

For the best finish, sand with a medium grit sandpaper. The product will also be more durable on a smoother surface. Fine wire wool can also be used to give a smooth finish but be sure to thoroughly brush away any residue afterwards. Steel residue can cause staining on hardwoods, particularly oak, as it reacts with the tannins.

Treat with Barrettine Mould and Mildew Cleaner

Before application, any dust or dirt should be removed by brushing. The wood should then be washed with Barrettine Mould and Mildew to kill any mould spores which may be present on the surface, preventing them from germinating in future. This should be permitted to dry for a minimum of 24 hours.

Treat with Barrettine Universal Preserver

For best results we recommended treating with 2 coats of Barrettine Universal Preserver before using ArmourFlex UV Protection Oil, sanding lightly between coats. This contains biocides to protect against wet rot, decay and wood boring insects. If using new pressure treated wood, this step is not necessary, but any cut ends/drill holes should be treated with Barrettine Cut End Preserver. Some wood types such as Cedar and Oak have some natural resistance to fungal attack, but Barrettine Universal Preserver will still provide additional protection against wood boring insects.

Application Conditions

Stir thoroughly with a flat-bladed paint stirrer before and during application, ensuring good ventilation (preferably apply outside). Protect areas not intended to be coated with impermeable sheeting/masking tape and if in doubt, confirm suitability before use.

The moisture content of the wood should not be above 20% and can be checked using a handheld moisture meter. The temperature during application and drying must be between 5-30°C, with no rain forecast within 12 hours. The relative humidity must be below 80% and ideally below 60%. If heavy rain has occurred recently, wait a minimum of 2 days for wood to thoroughly dry throughout. Application during cold or damp conditions will impact drying and may lead to a milky/hazy appearance as moisture becomes trapped in the finish.

Application Process

Apply 2-3 coats. Decant the product as needed and apply evenly using a high-quality brush and/or roller. The first coat can be applied generously until no further product will absorb into the wood. Subsequent coats should be applied sparingly. Beyond 2 coats, the gloss level will increase. The first coat on bare/weathered wood will absorb far more product than subsequent coats. Product can be re-coated after approximately 4 hours but will require a minimum of 10 hours to develop maximum water repellence. Protect from rain/frost until dry, to avoid damp becoming trapped within the finish.

| Components: | Single Pack |

| Type: | Wood Oil |

| Finish: | Dependent on application |

| Stock Colours: | Clear |

| Tintable: | No |

| VOC Content: | |

| Volume Solids: | |

| Suitable Substrates: | For exterior woodwork |

| Application Method: | Brush / Roller |

| Theoretical Coverage: |

Approximately 15-20m2/L per coat. This range depends on wood porosity and is based on smooth planed wood. Denser woods such as oak and iroko will absorb less, so will be at the higher end of the range than less dense woods, such as cedar, larch and pine. The product is not targeted at rough sawn woods but if used on these, the coverage would be expected to fall below 15m2/L. As a guide, a 1L tin will cover 8m2 with 2 coats, whilst a 2.5L tin will cover 20m2. |

| Wet Film Thickness (WFT): | |

| Dry Film Thickness (DFT): | |

| Induction Time: | - |

| Pot Life: | - |

| Dust Dry: | |

| Overcoatable: | |

| Fully Cured: | |

| Cleaner / Thinner: | Clean equipment with Barrettine White Spirit. Mop up any spills immediately with an absorbent cloth, then wipe with Barrettine White Spirit. Dried spills will require Barrettine Paint Panther or Peelaway 7 to remove, providing the surface below is compatible. |

| Shelf Life: | See container |

| Packaging: | Available in 1 and 2.5 Litres |