£7.75 delivery on orders excluding certain products & postcodes *

Hempel Hempadur EM 35740

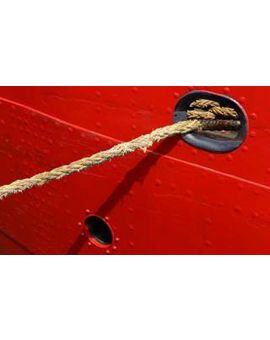

Hempel Hempadur EM 35740 is an ultra high solids and very low VOC epoxy coating, with good self priming properties.

Best Uses

Hempadur EM 35740 is best used for on-board corrosion maintenance on ships. Also, for spot repair in water ballast tanks and on decks. It is recommended for use in small areas that are hard to access, where climate control and surface preparation can be difficult.

Hempadur EM has also been specified for projects of the DLR and also for use on viaducts.

Application

You will first need to remove all oil, grease and any other contaminants using a suitable detergent, before applying EM 35740. Remove salts, detergents and other contaminants by high pressure fresh water cleaning.

In order to prevent re-rusting, the first coat must be applied immediately after surface preparation. No solvent must be added to the base, curing agent or to the mixed product.

Application should only be made by brush. Roller application will neither provide the water displacing effect, nor the specified dry film thickness per coat. Use intensive brushing and stippling in order to work the coating into the surface and displace any film of water. Avoid smoothing the applied paint excessively, as this may reduce the film thickness.

The minimum total dry film thickness should be 300μm/12 mil. This is best achieved by a simple step application process (wet on wet) which is particularly advantageous when more areas are repaired:

1) Apply and complete the first coat in one area

2) Leave the applied paint for approximately half an hour for an initial curing

3) During this time other areas can now be prepared or paint applied

4) Return to the first applied area and make a second application. The first coat will still be wet or tacky, this allows you to apply the second coat in a thick, coherent film to achieve the specified dry film thickness.

A wet film thickness gauge is recommended for control of the correct applied wet film thickness.

Approvals and Certificates

- Complies with US FDA and EU food regulations for contact with dry foodstuff.

Features and Benefits

- Damp surface tolerance

- Fast re-immersion

- Ultra high solids

- Very low VOC

Technical Info

| Components: | Two Component |

| Type: | Epoxy Coating |

| Finish: | Semi-gloss |

| Stock Colours: | 12170 Grey |

| Tintable: | No |

| VOC Content: | 52 g/L |

| Volume Solids: | 97 ± 2% |

| Suitable Substrates: | Ballast Tanks |

| Application Method: | Brush |

| Theoretical Coverage: | 6.5 m²/L |

| Wet Film Thickness (WFT): | 150µm |

| Dry Film Thickness (DFT): | 150µm |

| Induction Time: | - |

| Pot Life: | 1 hour at 20°C |

| Touch Dry: | 5.5 hours at 20°C |

| Hard Dry: | 9 hours at 20°C |

| Overcoating: | Minimum 120 minutes to maximum 10 days at 20°C |

| Cleaner / Thinner: | No thinning. Clean tools with Tool Cleaner 99610 |

| Shelf Life: | 3 years from date of production unopened |

| Packaging: | Available in 2.5 Litres |