£7.75 delivery on orders excluding certain products & postcodes *

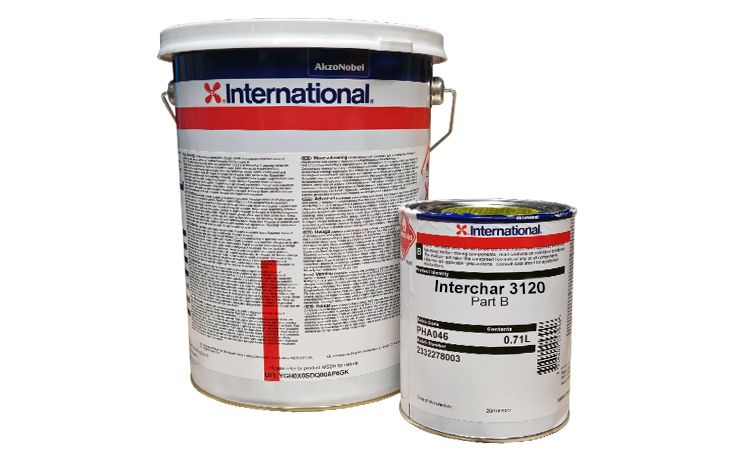

International Interchar 3120

International Interchar 3120 is a versatile, two-component, modified epoxy intumescent coating for cellulosic fire protection, providing a high quality, cosmetically appealing finish.

Best Uses

International Interchar 3120 is a low VOC and boron-free coating designed to provide fire protection to structural steelwork. Independently tested, assessed and certified, this product is suitable for use on both open and closed structural sections. Interchar 3120 is a spray applied material and does not require any form of reinforcement.

International Interchar 3120 is formulated to assist in preserving the structural integrity of steelwork in a cellulosic fire situation. Typical structures requiring this protection include a wide range of commercial, industrial, public and transport buildings e.g. airport terminals, leisure facilities, convention centres, high-rise buildings, educational facilities, shopping malls, industrial complexes and hotels.

Interchar 3120 utilises durable epoxy technology to provide a material that allows steelwork to be fabricated and fire-protected away from the construction site. Interchar 3120 has been designed to be extremely versatile and can be used direct to metal or over approved primers.

In addition, International Interchar 3120 can also be applied using single leg or plural spray equipment on ‘I’ sections, hollow sections and cellular beams.

Application

All steel surfaces to be coated should be clean, dry and free from contamination. Prior to paint application, all surfaces should be assessed and treated in accordance with ISO 8504-2000. Oil or grease should be removed in accordance with SSPC-SP1 solvent cleaning. Steel surfaces must be abrasively blast cleaned and suitably primed. Blast cleaning should be carried out to a minimum of Sa2½ (ISO 8501-1:2007) or SSPCSP6. The blast profile should be a minimum of 50 microns (2 mils) for steel substrates. Primer selection is based upon the final environment to which the fire protection system will be exposed.

Interchar 3120 can be applied directly to blast cleaned steel substrates for some service environments - see advice from International Protective Coatings. Surfaces should be prepared by blast cleaning to a minimum of Sa2½ (ISO 8501-1:2007) or SSPC SP6. A blast profile of minimum 50 microns (2 mils) must be achieved. Application should proceed before oxidation of the blast cleaned surface occurs.

Interchar 3120 can also be applied to galvanised steel substrates. Surfaces should be prepared by sweep abrasive blasting to provide a roughened surface, to a standard similar to Sa 1 (ISO 8501-1), SSPC-SP7 or NACE No. 4. Typically, a profile of 12-25 microns (0.6-1.0 mils) is achieved by sweep blasting. An approved primer should be applied after sweep blasting.

Apply via airless spray.

IMPORTANT INTUMESCENT PRODUCT NOTE: Always contact Promain’s technical team prior to purchase to obtain a tailored project specification and the advice necessary. The information displayed on this website should only be used as a guide. Promain UK Limited will not be held liable for any resulting damage to property, human life or monetary costs incurred due to incorrect specification, preparation, application or maintenance that has occurred due to negligence by either the purchaser or applicator. This includes your failure to have contacted us to obtain the relevant advice/specification.

Compatibility

Interchar 3120 has been tested as part of a coating system for use in fire situations over a wide range of approved priming systems:

- Intercure 200HS

- Intergard 2575

- Intergard 251

- Intergard 269

- Intergard 2511

- Interseal 1052

- Intergard 251HS

- Interseal 670HS

- Intergard 2509

- Interzinc 52

The following topcoats are recommended for Interchar 3120:

Technical Info

| Components: | Two Pack |

| Type: | Modified Epoxy |

| Finish: | Semi Gloss |

| Stock Colours: | Light Grey |

| Tintable: | No |

| VOC Content: | 0 g/L |

| Volume Solids: | 100% |

| Suitable Substrates: | Structural Steel |

| Application Method: | Airless Spray |

| Theoretical Coverage: | Contact our technical team for loadings |

| Wet Film Thickness (WFT): | Contact our technical team for loadings |

| Dry Film Thickness (DFT): | Contact our technical team for loadings |

| Induction Time: | - |

| Pot Life: | 45 minutes at 15°C |

| Touch Dry: | 16 hours at 15°C |

| Overcoatable: | With Self: After 6 hours at 15°C |

| Hard Dry: | 22 hours at 15°C |

| Cleaner / Thinner: |

|

| Shelf Life: | 12 months at 25°C (77°F). Subject to re-inspection thereafter. Store in dry, shaded conditions away from sources of heat and ignition. |

| Packaging: | Available in 25 Kg |