£9.95 delivery on orders excluding certain products & postcodes *

*Sika Sikafloor 235 ESD

Please note this product is now discontinued. Please contact our Technical Team on 01462 421333 to discuss a suitable alternative.

Sika Sikafloor 235 ESD is a 2-part, tough elastic, self smoothing, coloured electro static conductive epoxy resin coating. Sikafloor 235 ESD is the main wearing course of the Sikafloor® Multidur ES-25 ESD System and Sikafloor® Multidur ET-25 ESD Systems.

Best Uses

Sikafloor®-235 ESD may only be used by experienced professionals. Sikafloor 235 ESD is a decorative and protective dissipative self-smoothing system for concrete or cement screeds with normal up to medium heavy wear. Particularly suitable for areas with requirements for a low electrostatic charge (Body-voltage) and dissipative surface. Typical applications include industries that process, assemble, install, package, test or transport, such as clean room, pharmaceutical, automotive industries etc.

- Body voltage generation < 30 V *

- Good mechanical and chemical resistance

- Easy application

- Easy to clean & Liquid proof

- In accordance with general ESD requirements

- Fulfils ESD requirements at > 25 % RH/+23°C

Application

Concrete substrates must be sound and of sufficient compressive strength (minimum 25 N/mm2) with a minimum pull off strength of 1.5 N/mm2. The substrate must be clean, dry and free of all contaminants such as dirt, oil, grease, coatings and surface treatments, etc. If in doubt, apply a test area first. Concrete substrates must be prepared mechanically using abrasive blast cleaning or scarifying equipment to remove cement laitance and achieve an open textured surface.

Weak concrete must be removed and surface defects such as blowholes and voids must be fully exposed. Repairs to the substrate, filling of blowholes/voids and surface levelling can be carried out using appropriate products from the Sika Sikafloor®, SikaDur® and SikaGard® range of materials.

Wearing course smooth:

Sikafloor®-235 ESD is poured, spread evenly by means of a serrated trowel e.g. Large-Surface Scraper No. 656, toothed blades No. 25. After spreading the material evenly, turn the serrated trowel and smooth the surface in order to achieve an aesthetically higher grade of finish. Roll immediately (within max. 10 minutes of application) in two directions with a steel spiked roller to ensure even thickness and to remove entrapped air. To obtain the highest level of aesthetic finish, spike roll in two directions at a 90 degree angle, passing only once in each direction.

Wearing course textured:

Sikafloor®-235 ESD (+ Thinner C & Extender T) is applied with a serrated trowel e.g. Trowel No. 999 or Adhesive Spreader No.777, toothed blades No. 23 = A3 and then back-rolled (crosswise) with a textured roller.

Approvals

- Sikafloor®-235 ESD conforms to the requirements of LEED EQ Credit 4.2: Low-Emitting Materials: Paints & Coatings SCAQMD Method 304-91 VOC Content < 100 g/l

- Self-smoothing, coloured epoxy resin coating according to EN 1504-2: 2004 and EN 13813, DoP 02 08 01 02 037 0 000005 2017, certified by Factory Production Control Body No. 0921, certificate 2017, and provided with the CE-mark

- Testing of electrostatic properties in accordance to IEC 61340-5-1, Polymer Institute, Test Report P 4956-1-E, November 2007

- Testing of electrostatic properties in accordance to IEC 61340-5-1, SP Institute, Test Report F900355:B, February 2009

- Conforms to the requirements of ANSI/ESD S20.20 and IEC 61340-5-1. (Internal Test)

- Fire classification in accordance with EN 13501-1, Report-No. 2007-B-0181/18, MPA Dresden, Germany,May 2007

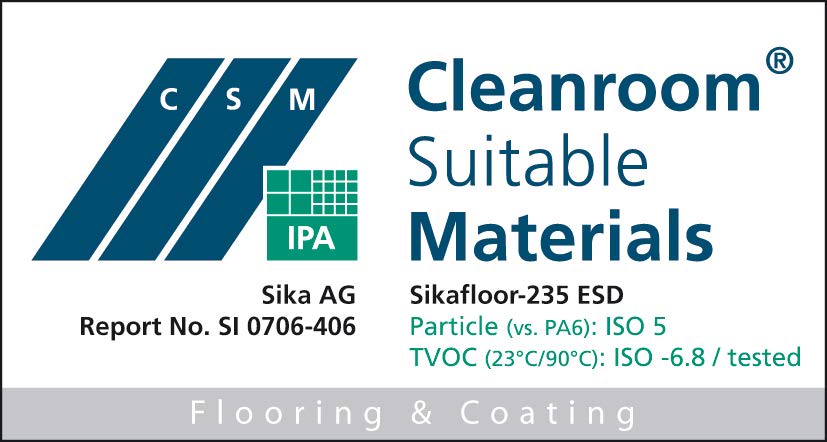

- Particle emission certificate Sikafloor-235 ESD CSM Statement of Qualification - ISO 14644-1, class 4 - Report No. SI 0706-406 and GMP class A, Report No.

SI1008-533 - Outgassing emission certificate Sikafloor-235 ESD: CSM Statement of Qualification - ISO 14644-8, class - 6.8 - Report No. SI 0706-406

- Testing of Paint Compatibility in acc. to BMW-Standard 09-09-132-5, Polymer Institute, Test Report P 5541, August 2008

- Varnishability test according to Mercedes Benzstandard PBODC380/PBVCE380 (paint wetting impairment substances (PWIS)) like silicones, Test Report

VPT-Nr. 07LL165, 04.2008 - Spark resistance in accordance with UFGS-09 97 23 of coating systems, Test report P 8625-E, Kiwa Polymer Institut

Systems

Sika Sikafloor 235 ESD is used within the following Sika systems:

- Sikafloor MultiDur ET-25 ESD

- Sikafloor MultiDur ES-25 ESD

See Data Sheets tab for System sheet downloadable PDF

Notes

- Electrostatic Behaviour: Resistance to ground1) Rg < 109 Ω, Typical average resistance to ground2) Rg < 106 Ω, Body voltage generation2) System < 100 V, Resistance (Person/Floor/Shoe)3) < 35 M Ω

Technical Info

| Components: | Two Part |

| Type: | Epoxy Electrostatic Resin |

| Finish: | |

| Stock Colours: | Only tints |

| Tintable: |

Almost unlimited choice of colour shades. Please note, bespoke tints are non refundable / exchangable. Due to the nature of carbon fibres providing the conductivity, it is not possible to achieve exact colour matching. With very bright colours (such as yellow and orange), this effect is increased. Under direct sun light there may be some variations and colour variation, this has no influence on the function and performance of the coating. |

| VOC Content: | 100.0g per Litre |

| Volume Solids: | 100% |

| Suitable Substrates: | For concrete or cement screeds with normal up to medium heavy wear |

| Application Method: | Serrated Trowel e.g. Large-Surface Scraper No. 656, Toothed blades No. 25 and Roller |

| Theoretical Coverage: |

Maximum 2.5 Kg per m2 Binder + quartz sand F34 Depending on the temperature the filling grade varies 0.7 - 0.8 Kg m2 - 1.5 - 2% (by weight) - For film thickness approx 0.5mm |

| Wet Film Thickness (WFT): | |

| Dry Film Thickness (DFT): | |

| Induction Time: | - |

| Pot Life: | 25 minutes at 20°C |

| Foot Traffic: | 3 days at 20°C |

| Light Traffic: | After 6 days at 20°C |

| Fully Cured: | 7 days at 20°C |

| Cleaner / Thinner: | Sika Thinner C |

| Shelf Life: | 12 months from date of production |

| Packaging: | Available in 25 Kg |